Welcome to My Blog!

Before we dive into the content, I’d love for you to join me on my social media platforms where I share more insights, engage with the community, and post updates. Here’s how you can connect with me:

Facebook:https://www.facebook.com/profile.php?id=61567891941530

Now, let’s get started on our journey together. I hope you find the content here insightful, engaging, and valuable.

Caisu Machinery sells a variety of used plastic pipe production equipment. The products are of high quality and low price. Welcome to contact us for consultation and purchase. We will be happy to serve you.

Table of Contents

Introduction

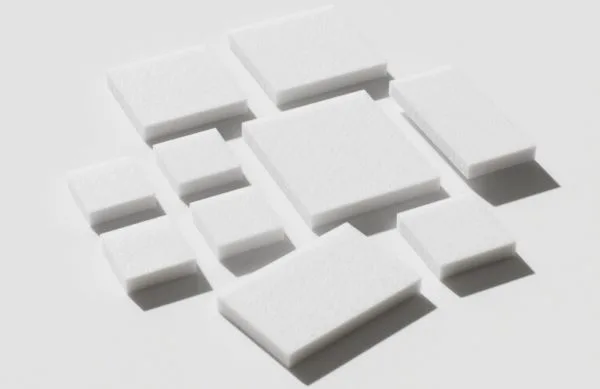

In industries where durability, aesthetics, and ease of fabrication matter, foam PVC boards have carved out a vital niche. Whether you’re in signage, furniture, building construction, or even boat interiors, these boards offer an unbeatable balance between strength and weight. But what makes foam PVC boards so popular, especially when sourced through high-quality manufacturing or recycled production lines?

This article will give you a complete understanding of foam PVC boards—their material properties, applications, and why they’ve become a go-to solution in multiple sectors. We’ll also explore how second-hand PVC board production equipment can be a game-changer in terms of cost-efficiency and sustainability.

What Are Foam PVC Boards Made Of?

Foam PVC boards are crafted using a combination of polyvinyl chloride resin, modifiers, and foaming agents. The manufacturing process involves extrusion, where the raw materials are heated and pushed through a mold to form a lightweight yet rigid sheet. The “foamed” core gives the board its signature low density, while the outer skin remains smooth and durable.

Thanks to this unique structure, foam PVC boards are resistant to moisture, chemicals, and UV exposure, making them suitable for both indoor and outdoor use. The closed-cell surface also makes them easy to clean and ideal for applications requiring hygiene, such as hospital partitions or kitchen cabinets.

Key Benefits of Foam PVC Boards

Here’s why more manufacturers, builders, and designers are turning to foam PVC boards:

- Lightweight but sturdy – Easy to transport and install

- Weather-resistant – Won’t rot or corrode outdoors

- Excellent printability – Perfect for digital printing and signage

- Waterproof and non-toxic – Safe for interior use

- Thermoformable – Easily bent or shaped with heat

Table: Technical Comparison of Foam PVC Board Properties

| Property | Foam PVC Boards | Traditional Plywood | MDF (Medium Density Fiberboard) |

|---|---|---|---|

| Weight | Very light | Moderate to heavy | Heavy |

| Water Resistance | Excellent | Poor | Poor |

| Fire Retardant Options | Available | Limited | Limited |

| Surface Finish | Smooth and uniform | Grainy | Smooth but less durable |

| Workability | Easy to cut, shape, print | Requires tools | Brittle edges when machined |

| Cost-Efficiency with Used Lines | High | Moderate | Moderate |

Popular Applications for Foam PVC Boards

Foam PVC boards are incredibly versatile and find use in a wide range of industries. If you’re using or considering a second-hand plastic extrusion line, these boards open up business potential across several verticals.

- Advertising and Display: Ideal for printing and signage due to their smooth surface and vibrant color absorption.

- Furniture and Cabinetry: Water resistance makes them suitable for kitchens, bathrooms, and outdoor furniture.

- Wall and Ceiling Panels: Used in residential and commercial interiors for clean, low-maintenance finishes.

- Transport and Marine: Lightweight properties make them perfect for van linings and boat interiors.

- Construction: Used in temporary structures, partitions, and formwork in building projects.

According to recent reports from construction materials trade associations, foam PVC boards have seen a growth in global demand of over 6% annually due to rising interest in sustainable, multi-functional building materials.

Second-Hand PVC Foam Board Production Lines: A Smart Investment

You don’t always need brand-new machinery to produce high-quality foam PVC boards. Many manufacturers opt for well-maintained second-hand plastic machinery for several reasons:

- Lower Capital Investment: Significant cost savings without compromising production quality.

- Proven Performance: Used equipment from mature manufacturing lines is often well-tested and stable.

- Quick Setup and Scalability: Immediate availability and faster integration into existing workflows.

In fact, many businesses around the world are choosing refurbished PVC foam board extrusion machines to scale production and reduce operational risk.

Conclusion

Whether you’re a manufacturer, fabricator, or distributor, foam PVC boards offer you a lightweight, durable, and flexible material that meets modern industrial needs. They’re easy to work with, cost-efficient, and ideal for a wide array of applications.

And if you’re considering expanding your production capabilities or starting a new business with a lower investment threshold, second-hand foam PVC board production equipment can give you a running start—without sacrificing quality.

If you’re exploring foam PVC board solutions or looking to source reliable extrusion machinery, especially refurbished lines, our experienced team can help. We’ve supported countless businesses with tailored recommendations that match their capacity and goals.

Ready to start producing foam PVC boards? Contact us today to explore our range of second-hand plastic machinery and customized support.

FAQ

Are foam PVC boards eco-friendly?

Yes, they can be recycled and reused. Also, when using second-hand equipment, the environmental impact is further reduced by minimizing manufacturing waste.

Can foam PVC boards be used outdoors?

Absolutely. Their resistance to moisture, UV rays, and weathering makes them ideal for exterior signage and cladding.

What’s the difference between foam PVC and solid PVC sheets?

Foam PVC has a cellular structure, making it lighter and easier to handle. Solid PVC sheets are denser, heavier, and often more expensive.

Is foam PVC safe for interior applications?

Yes, it’s non-toxic and can be used in food-safe or medical environments, provided it’s manufactured under quality standards.

Can I produce foam PVC boards with used plastic machinery?

Definitely. As long as the machinery has been inspected and maintained, second-hand production lines can deliver excellent quality.